Automatic Water Level Controllers In Bangalore

- Devaraju HM

- Sep 8, 2025

- 2 min read

Never Run Dry: The Magic of Automatic Water Level Controllers

Have you ever experienced the frustration of a sudden dry tap, or worse, a flooded overhead tank? In a bustling city like Bengaluru, efficient water management is not just a convenience, it's a necessity. That's where Automatic Water Level Controllers come into play!

What is an Automatic Water Level Controller?

An Automatic Water Level Controller (AWLC) is an electronic device designed to monitor and control the water level in overhead tanks and sumps. Its primary function is to automatically switch on the motor pump when the water level in the overhead tank drops below a certain point and switch it off when the tank is full. This intelligent system ensures a continuous water supply while preventing wastage and saving energy.

How Does it Work?

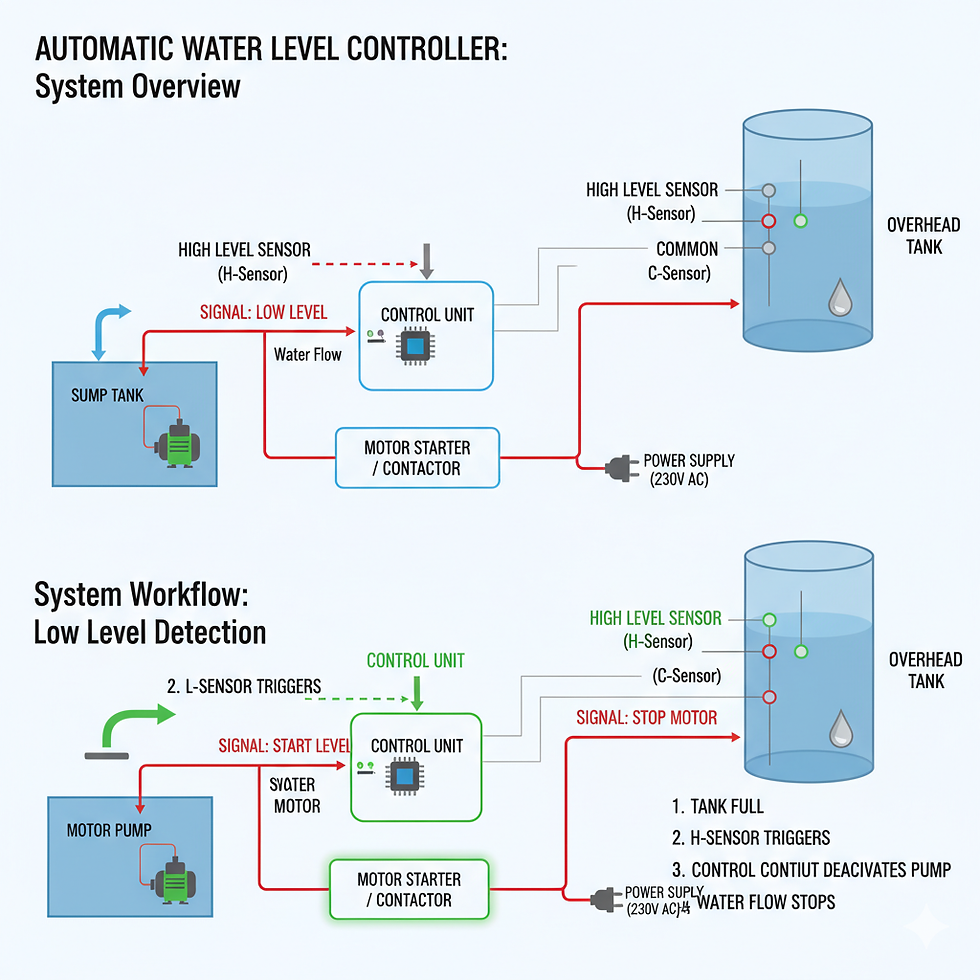

an AWLC typically uses a combination of:

Sensors: These are the "eyes" of the system. Common types include:

Float Sensors: Mechanical switches that trigger based on water level.

Conductivity Sensors: Detect water presence by measuring electrical conductivity between probes.

Ultrasonic Sensors: Emit sound waves and measure the time it takes for them to bounce back, determining the water level. The choice of sensor often depends on the application's accuracy and cost requirements.

Control Unit (Microcontroller/Relay Logic): This is the "brain." It receives signals from the sensors and processes them. Based on pre-programmed logic, it decides when to turn the motor on or off. Many modern AWLCs use microcontrollers for more sophisticated control and features.

Motor Starter/Contactor: This robust electrical switch handles the high current required to operate the water pump. The control unit energizes or de-energizes the contactor to switch the motor.

The Workflow:

Low Level Detection: When the water in the overhead tank falls below the "low level" sensor, the control unit receives a signal.

Pump Activation: The control unit then sends a signal to the motor starter, which switches on the water pump.

High Level Detection: As the tank fills, water reaches the "high level" sensor.

Pump Deactivation: The control unit receives this signal and switches off the motor pump, preventing overflow.

Key Benefits for Bangalore Homes & Businesses

No More Dry Taps: Enjoy an uninterrupted water supply.

Prevents Overflow & Wastage: Say goodbye to overflowing tanks and wasted water – a critical concern in water-stressed regions.

Energy Savings: The motor runs only when necessary, leading to significant reductions in electricity bills.

Increased Pump Lifespan: Reduced wear and tear on your pump due to optimized operation.

Convenience: No more manual monitoring or switching pumps on and off.

Peace of Mind: Relax, knowing your water levels are perfectly managed.

Choosing the Right AWLC: What to Consider

Type of Tank: Overhead, sump, or both?

Motor Horsepower: Ensure the controller can handle your pump's power rating.

Sensor Type: Conductivity, float, or ultrasonic?

Features: Dry run protection, indicator lights, manual/auto modes, alarm systems.

Installation: Professional installation is recommended for optimal performance and safety.

The Future of Water Management is Automated!

As Bengaluru continues to grow, smart solutions for resource management become increasingly vital. Investing in an Automatic Water Level Controller is a step towards a more sustainable, convenient, and worry-free water supply for your home or business. Don't wait for your taps to run dry – automate your water management today!

Comments